Foliant Vega 400A Laminator

Foliant Vega 400A Laminator

Description

Now in stock at Glendale we have this Foliant Vega 400A Automated Laminator. This B3+ Foliant Vega 400A is working perfectly. Speeds of 18 metres per minute can be reached offering production of over 2300 SRA3 and 2100 B3 sheets per hour. Also includes the optional jogger reception and non-sticky pressure roller.

The Foliant Vega 400A is a new generation of easy available very compact industrial laminating machines, designed for a heavy duty digital outputs and B3 litho lamination, with an integrated deep pile vacuum feeder and a high speed bump separator, with non-sticky pressure roller and in-run adjustable twin decurl bar and overlap system. Due to its pneumatic high pressure system (with integrated compressor inside machine frame), format and performance, the machine is suitable for all jobs – all kinds of digital printed sheets and high volumes of offset printed sheets size B3+ lamination too. The machine maximum running speed is up to 18 m/min.

Feeder

The Foliant Vega 400A is equipped with a rising pile front separation stream feeder and with a vacuum belt head. The built-in Becker vacuum pump is used for sheets front airing and feeding head vacuum. The overlaps are controlled, in an"in-run" mode. The accuracy is +/- 2 mm under-lap (in a constant speed). The feeder is fitted with a lifting plate and its capacity is a 300mm pile of paper.

Laminator

The Foliant Vega 400A laminator maximum sheet size is 380mm x 660mm. The minimum sheet size is 200 x 300mm.The Folinat Vega 400A machine is a single sided thermal industrial laminator, capable of laminating 115-500 gsm paper. This lamiantor does not need any external source of pressured air for the pneumatic pressure system, this is because the compressor is integrated inside the machine frame as a standard delivery.

The laminating unit is equipped with an adjustable twin decurl unit:

With a decurl blade for offset printed sheets decurling

With a decurl roller for digital printed sheets decurling

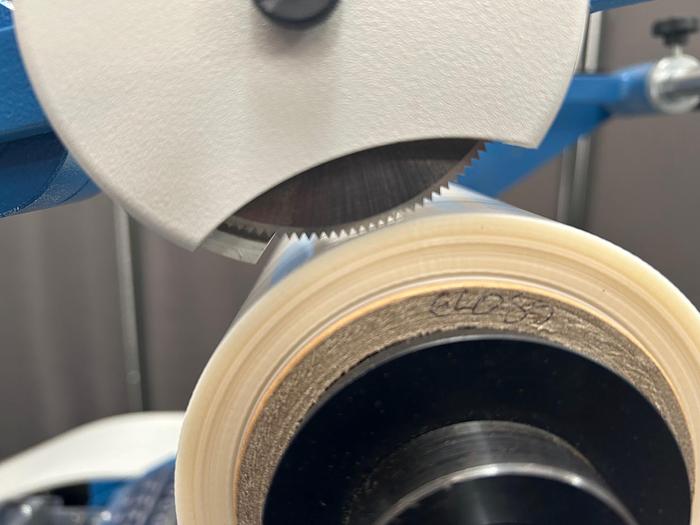

The roll of a film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 3000 m of the 22 - 42 microns film. The film holder unit is equipped with an in-line trim slitter and a perforating wheel. The laminating process is made between two laminating rollers - a highly polished chrome roller, and a lower hard rubber pressure roller with non-sticky surface. The pressure is pneumatically adjustable. The laminating roller is heated with a dry electric system inside the roller, with a sensitive temperature sensor. The warming up time is shorter than 10 minutes. The whole laminator is control with an interactive, easy understandable icon based touch screen and its used control system includes many automation items for an easy control of the machine and a reliable lamination.

Separator

The integrated bump separator is equipped with a pair of fast cycling rollers. The process is controlled from the machine control unit. The separated sheets are delivered into the optional jogger which is included in this system.

Specifications

| Manufacturer | Foliant |

| Model | Vega 400A |

| Condition | Refurbished |

| Max sheet size | 380mm x 660mm |

| Min sheet size | 200mm x 300mm |

| Paper weight | 115gsm - 500gsm |

| Max speed | 18 metres per minute |

| Laminating roller pressure | Pneumatic |

| Feeder | Automatic Suction Vacuum Belt |

| Seperator | Automatic bump rollers |

| Decurl bar | Standard - in run adjustable |

| Air compressor | Integrated as standard |

| Warm up time | 8 minutes |

| Temperature range | 80 - 140°C |

| Jogger reception | Included |

| Power requirement | 230/240v 50/60Hz |

| Machine weight | 370kg |

| Machine dimensions with jogger | (L)1980mm x (W)820mm x (H)1230mm |